Global Leader in ALD Technology

- COMPANY

- News

News

Metal mask coating by ALD for reliable plasma process in PECVD

작성자 : 최고관리자

등록일 : 20-01-13 11:05

관련링크

본문

PECVD method with metal masks has been generally used to deposit inorganic layers like SiNx and SiO2 for manufacturing LCD and OLED displays.

However, this plasma process has severe problems like plasma arcing or particle generation due to instability of electrical isolation between the metal mask and the showerhead as a RF electrode. So the metal mask should be required to deposit dielectric materials such as Al2O3, Y2O3, TiO2, MgO, ZrO2, etc. on it to prevent plasma damage.

Generally, the dielectric layer is coated by sputtering method which is a typical physical vapor deposition (PVD). However, this method is difficult to coat uniformly the metal mask with large area and complex structure as well as it has the disadvantage of requiring a thick deposition of several µm and multiple processes.

In order to obtain excellent electrical isolation properties of metal masks in PECVD process, the atomic layer deposition (ALD) of Al2O3 thin film might be the best solution which enables getting uniform deposition on them with large area and complex structure.

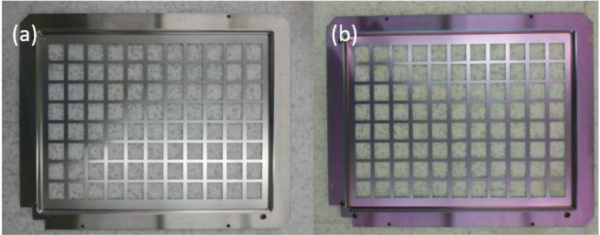

ALD Al2O3 layers could give them remarkable electric isolation and great protection even if the thickness is less than one ㎛. When 50nm ~ 200nm layers of Al2O3 deposited by NCD large-area demo tool on metal masks were applied to the PECVD process, there was no issues like plasma arcing or damage.

[Images of metal mask coated by ALD with Al2O3 a) before (b) after]

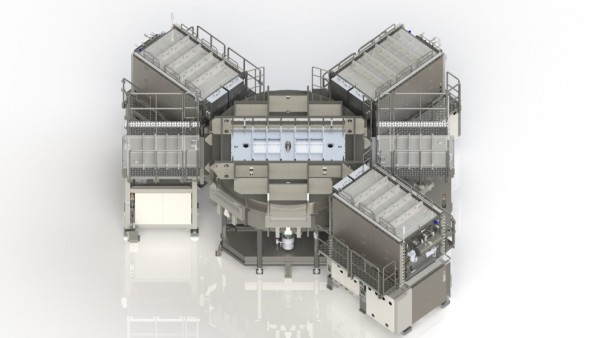

In fact, even though ALD Al2O3 has lots of advantages, the end customer has to consider of low throughput using general large-area ALD equipment. So NCD’s Lucida GD Series for large-area ALD applications might be the most suitable equipment with superb productivity to provide superior protective layers to the metal masks from plasma issues in PECVD process.

NCD has steadily developed large area and high throughput ALD equipment and technology. The applications for display, solar cell, and semiconductor fields have been already commercialized, and also NCD has worked hard to find use in special markets like excellent plasma protective coating on metal masks. NCD will aggressively respond to the development and then supply of ALD equipment which customers would need for various industries in the future.

[LucidaTM ALD system for metal mask coating]

However, this plasma process has severe problems like plasma arcing or particle generation due to instability of electrical isolation between the metal mask and the showerhead as a RF electrode. So the metal mask should be required to deposit dielectric materials such as Al2O3, Y2O3, TiO2, MgO, ZrO2, etc. on it to prevent plasma damage.

Generally, the dielectric layer is coated by sputtering method which is a typical physical vapor deposition (PVD). However, this method is difficult to coat uniformly the metal mask with large area and complex structure as well as it has the disadvantage of requiring a thick deposition of several µm and multiple processes.

In order to obtain excellent electrical isolation properties of metal masks in PECVD process, the atomic layer deposition (ALD) of Al2O3 thin film might be the best solution which enables getting uniform deposition on them with large area and complex structure.

ALD Al2O3 layers could give them remarkable electric isolation and great protection even if the thickness is less than one ㎛. When 50nm ~ 200nm layers of Al2O3 deposited by NCD large-area demo tool on metal masks were applied to the PECVD process, there was no issues like plasma arcing or damage.

[Images of metal mask coated by ALD with Al2O3 a) before (b) after]

In fact, even though ALD Al2O3 has lots of advantages, the end customer has to consider of low throughput using general large-area ALD equipment. So NCD’s Lucida GD Series for large-area ALD applications might be the most suitable equipment with superb productivity to provide superior protective layers to the metal masks from plasma issues in PECVD process.

NCD has steadily developed large area and high throughput ALD equipment and technology. The applications for display, solar cell, and semiconductor fields have been already commercialized, and also NCD has worked hard to find use in special markets like excellent plasma protective coating on metal masks. NCD will aggressively respond to the development and then supply of ALD equipment which customers would need for various industries in the future.

[LucidaTM ALD system for metal mask coating]